The alliance

The project “DA-GATE

– the Danish Alliance of Graphene Application Technology and Engineering” aims at establishing a powerful alliance consisting of leading Danish and international high tech companies and experts from Danish academic institutions, with the common goal of exploring the potential of graphene for industrial applications.

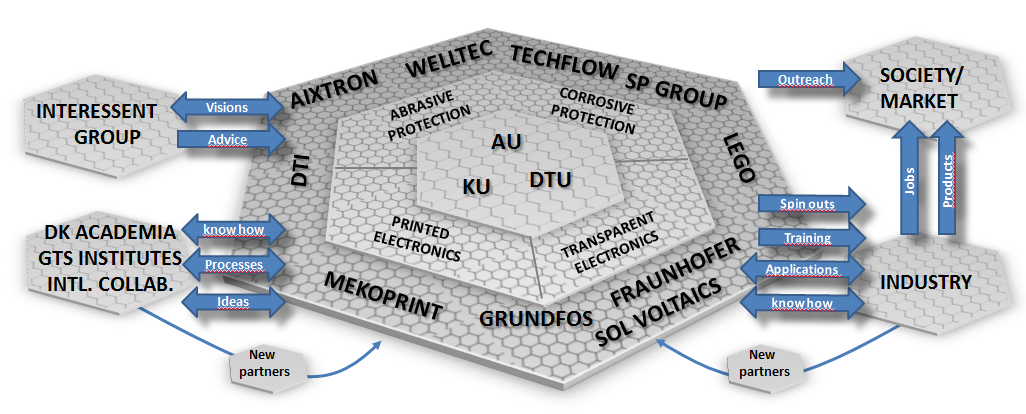

DA-GATE is headed by Associated Professor Peter Bøggild from the Technical University of Denmark (DTU Nanotech). The other partners in the project include; the University of Copenhagen (Nanoscience Center, KU), Aarhus University (INANO, AU), Welltec, Mekoprint, LEGO, SP Group, Grundfos, Fraunhofer, Techflow, DTI, Aixtron and SOL Voltaics.

Figure: Conceptual diagram illustrating the partners and research areas in DA-GATE

Focus areas

DA-GATE addresses key challenges in graphene production. In the project’s four-year-run, it will focus on three main areas:

-

Production of high quality graphene for solar cells and transparent OLEDs (organic light emitting diodes)

-

Passivating graphene coatings for corrosion protection of stainless steel and other materials

-

Conducting ink for printed electronics

DA-GATE wants to form a technology “gate” through which Danish companies can approach graphene production technology and benefit from this revolution in material technology.

Perspectives

Graphene can be fabricated in different ways, with a characteristic tradeoff between quality and quantity. While different forms of graphene address different application areas, a common challenge is to improve this tradeoff with respect to production. Also transferring of graphene to different surfaces is an exceedingly important issue. The transfer processes known today are typically difficult and unreliable, involving the use of expensive, dangerous and harsh chemicals or awkward handling of the atomically thin sheets, and often results in damage or contamination and increased cost. We will develop three complementary types of graphene and adapt these to practical applications:

-

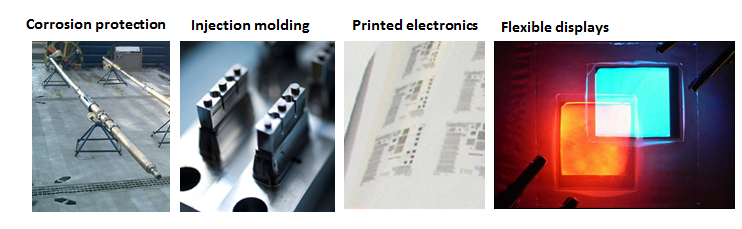

Single-crystal chemical vapor deposited graphene for high quality transparent electrodes and solar cells

-

Single- or multilayer graphene for tribocorrosive protection of stainless steel in oil/geothermal well robots as well as molding and packaging machines

-

Reduced graphene oxide for printable functional materials.

Together these activities cover the spectrum from high quality graphene for critical applications to cheap printable graphene material, and thus make graphene available for industrial assessment in a range of practical applications, even beyond the projected prototypes.

Figure: Overview of the specific technologies/products the alliance is aiming to develop